16mm UFH Pipe - PEX Underfloor Heating - PEX-AL-PEX Barrier Pipe 100m, 150m, 200m, 250m, 300m, 400m, 500m coils 2.0mm Wall Thickness Insulated Multi-layer WRAS Approved

Note -the total meterage ordered is not a single coil and may be made of of 2 coils ie. if you order 400m total, you may get 2 x 200m. In the unlikely event your using 400m in one run you simple use a connector/coupler If this is a problem please contact us BEFORE ordering as we dont cover return costs for unwanted goods.

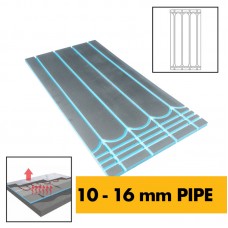

Click here to purchase the 25mm insulated UFH Boards 1200mm x 600mm.

At 150mm centres, each single 1200mm x 600mm UFH board requires approx 4.8m of pipe or

OR

6.6 linear metres of pipe per sq m flooring.

ie. 100m pipe = 20 boards = 14.4sqm. See table below for full calculations or contact us for a quote. (this calculation only covers the boards, it doesnt cover to get to and from manifold, returns waste etc. so we recommend purchasing 15% extra)

16mm UFH Pipe – PEX Underfloor Heating – PEX-AL-PEX Barrier Pipe – 100m, 150m, 200m, 250m, 300m, 400m, 500m Coils – 2.0mm Wall Thickness Insulated Multi-layer WRAS Approved.

Click here to purchase the 25mm insulated UFH Boards 1200mm x 600mm. At 150mm centres, each board require approx 4.8m of pipe or 6.6 linear metres of pipe per sq m flooring. ie. 100m pipe = 20 boards = 14.4sqm. See table below for full calculations

[High quality PEX-AL-PEX construction] Multi-layer composite pipe with an aluminium core for shape memory and stability, sandwiched between layers of durable PEX for flexibility, strength, and long service life in wet underfloor heating systems and more durable than cheaper PERT-AL-PER types on the market.

[WRAS Approved for heating systems] Certified safe for use with drinking water as well as heating installations, ensuring compliance with UK building regulations and peace of mind for all domestic and commercial projects.

[Excellent thermal efficiency with 2.0mm wall thickness] Designed for fast heat transfer, optimal system performance, and energy saving, while maintaining flexibility for easy installation around tight bends and returns.

[Available in multiple coil lengths for any project size] Supplied in convenient 100m, 150m, 200m, 250m, 300m, 400m, and 500m coils to suit small domestic rooms or full property installations without unnecessary joins.

[Corrosion resistant, flexible & easy to install] The aluminium barrier prevents oxygen diffusion, protecting boilers and pumps from corrosion. Flexible yet robust pipe is easy to handle and lay, ideal for screeded or board-based underfloor heating systems.

| Sq Meterage | No of UFH Boards | Linear Metres of UFH Pipe |

| 4 | 6 | 29 |

| 5 | 7 | 34 |

| 6 | 9 | 43 |

| 7 | 10 | 48 |

| 8 | 12 | 58 |

| 9 | 13 | 62 |

| 10 | 14 | 67 |

| 12 | 17 | 82 |

| 14 | 20 | 96 |

| 16 | 23 | 110 |

| 18 | 25 | 120 |

| 20 | 28 | 134 |

| 25 | 35 | 168 |

| 30 | 42 | 202 |

| 35 | 49 | 235 |

| 40 | 56 | 269 |

| 45 | 63 | 302 |

| 50 | 70 | 336 |

| 75 | 105 | 504 |

| 100 | 140 | 672 |

| 125 | 175 | 840 |

| 150 | 210 | 1008 |

| 200 | 280 | 1344 |

Boards are price individually and only sold in packs/multiples of 5 hence you may need to round up to the nearest 5 ie. 5, 10, 15, 20, 25 etc...

Property |

Assessed to |

Rating |

||||||

| Density | DIN 53420 | 32 kg/m3 | ||||||

| Thermal Conductivity (initial) | DIN 52612 | 0.034 Watt/mK | ||||||

| Thermal Conductivity (>5yrs) | ASTM C518 | 0.036 Watt/mK | ||||||

| Compressive Strength (10% deflection) | DIN 53421 | Minimum of 0.3N/mm2 | ||||||

| Flexural Strength | ASTM C203 | 0.30 ±0.02 MPa | ||||||

| Water Absorption (2-day immersion) | ISO2896 | 0.2% by volume | ||||||

| Water Absorption (Capillary) | DIN 53428 | Zero | ||||||

| Coefficient of linear expansion | N/A | 70 x 10-6 K-1 | ||||||

| Water Vapour Diffusion Resistivity (µ) | DIN 52615 | 110 - 225 µ | ||||||

| Water Vapour Permeability | ASTM E-96 | 0.028 ng/Pa.m.s | ||||||

| Fire Euroclass | BS EN 13501-1 | Class E |

Installation

The installation method for XPS foam insulation boards depends on the type of heating system being installed:

- Wooden floor Heating System: Lay the boards in a staggered brick bond pattern, secure with screws and washers.

- Tiled floor - the boards must be securely fixed to the subfloor using a suitable flexible tile adhesive. Screed or tile directly due to the boards cement coated surface.

-main-250x250.jpg)